Step 1. Mixing Process

The ‘mixing Process’ involves adding and mixing

various chemicals to crude rubber according to the characteristics and

intended use of each tire. Rubber sheets are created by adding

plasticity to rubber so that its shape does not change easily.

Step 2. Extrusion Process

Once rubber sheets are made according to the

characteristics of each part of the tire through the ‘mixing

Process,’ rubber is then created into a certain regular width and

thickness through the ‘extrusion process.’ Here, the treads

(outer surface of the tire) and sidewalls (sides of the tire) are

created, which is an important process for cozy and comfortable driving.

Step 3. Calendering Process

The ‘calendering Process’ involves evenly

applying and thinly topping a certain thickness of rubber sheets created

in the ‘mixing Process’ on both sides of steel cords and

fabric cords. Rubber is coated on the front and back by pushing steel

cords and fabric cords through the constantly rolling rollers. Tires can

endure the car weight and maintain a certain form due to this

‘calendering Process’ (cords).

Step 4. Bead Process

The ‘bead process’ is the process of coating

steel wires with rubber multiple times in a certain thickness, and

attaching filler rubber here. Beads fix the rubber of the tires to the

wheels, serving as the frame of tire rims and thus making the tires

stronger if there are more beads.

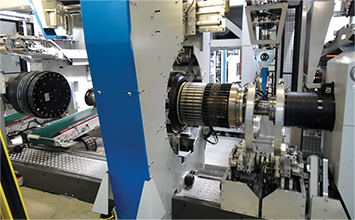

Step 5. Building Process

Now, there is the ‘building Process’ in which

cylindrical green tires are made by consecutively attaching all

components and materials used in tires to the molding press. This

‘building Process’ requires a great of attention since it

determines the quality of the tires. Radial tires used in automobiles

first require the process of attaching the ‘carcass’ (the

frame of the tire located inside the tread), ‘beads’ (the

frame fixed on the rim of wheels), and ‘sidewalls.’ Then,

they are transferred to the secondary molding press to complete tires by

attaching belts and treads.

Step 6. Curing Process

The ‘curing process’ involves adding heat and

pressure inside and outside by putting tires made of flexible rubber in

a fixed mold. Sulfur and other chemicals react to rubber and create a

unique design of NEXEN TIRE on the tread, and also apply elasticity to

the rubber. Also, they provide any desired structure, shape, exterior,

and mechanical/chemical characteristics.

Step 7. Test Process and Shipping

The ‘test process’ consists of five detailed

tests.

First, there is the ‘visual test’ that inspects the

exterior and interior of the tire as well as the bead with the naked eye.

Second, there is the testing of the tire as a single product before

assembling on the wheel, and also whether the tire weight distribution is

consistent in the circumferential direction (*direction of ultrasonic beam

that is vertical to the main shaft of the cylindrical device) in the static

state. Third, there is the ‘dynamic balance test’ that measures

the weight uniformity in the circumferential direction after rotation when

the tires are assembled on the wheels and optimal air pressure is put into

the tires. Fourth, there is the ‘uniformity test’ that tests the

uniformity of size and rigidity of the product. Finally, x-rays are used to

test the carcass inside the tires, structure of belts, and mixing of foreign

matters, after which the manufactured products are automatically classified

and shipped.